Technologies

Technologies

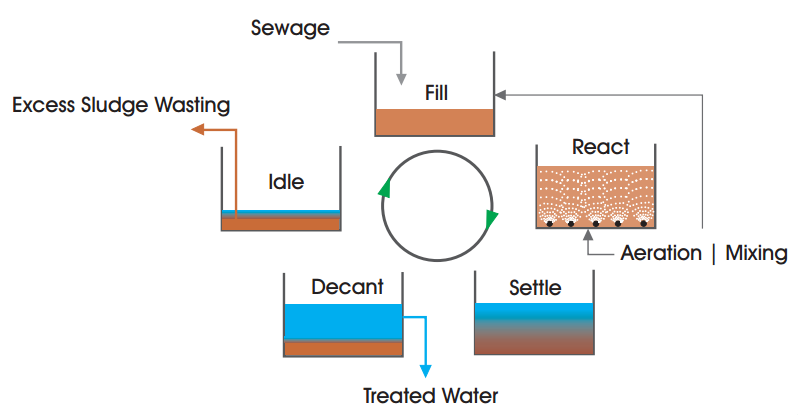

Sequential Batch Reactor (SBR)

The SBR is fundamentally the same as any other variation of activated sludge. The same concepts, design procedures, and biological kinetics used for continuous flow systems are applicable to the design and operation of SBRs. However, the impacts of a batch operation compared to continuous flow systems must be understood and applied for a successful SBR system.

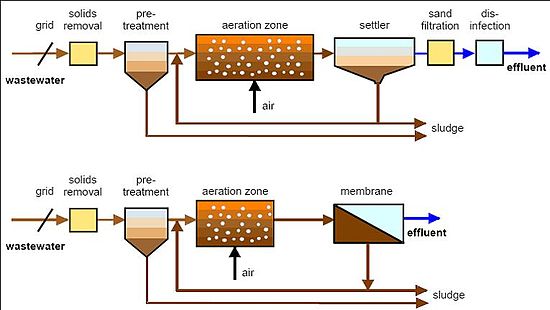

Membrane Bio Reactor (MBR)

The membrane bioreactor (MBR) technology represents an advanced activated sludge wastewater treatment process that is capable of producing a suspended solids-free, tertiary treated quality effluent. The process combines a biological reactor with a membrane filtration system, for retention of the activated sludge. The most common MBR process configuration for the treatment of domestic wastewater involves direct in-situ filtration of mixed liquor by immersed microfiltration or ultrafiltration membranes, eliminating the need for external clarification and filtration.

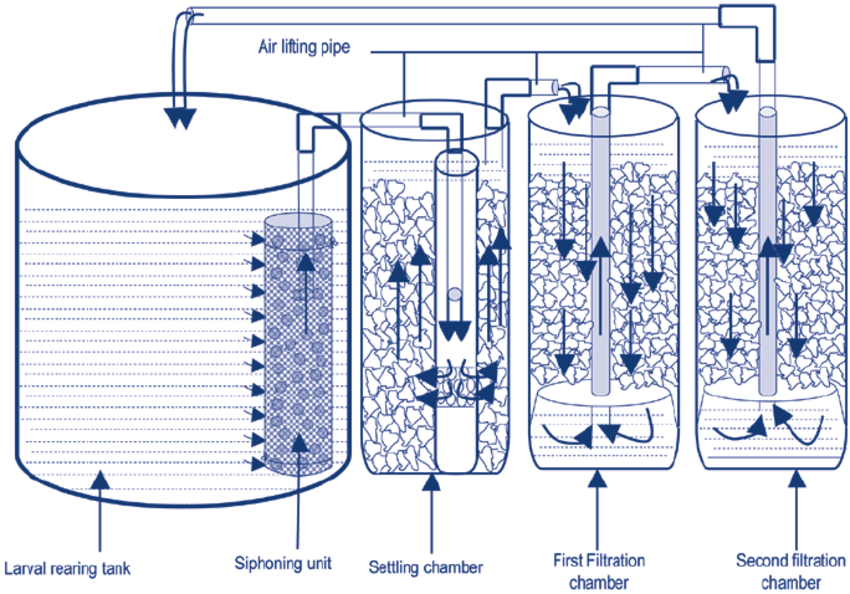

Bio Filter

Bio filter is an attached growth process i.e. process in which microorganisms responsible for treatment are attached to an inert packing material. Packing material used in attached growth processes include rock, gravel, slag, sand, redwood, and a wide range of plastic and other synthetic materials. The wastewater in trickling filter is distributed over the top area of a vessel containing non-submerged packing material. Air circulation in the void space, by either natural draft or blowers, provides oxygen for the microorganisms growing as an attached biofilm. Packing are the means of providing large amounts of surface area where the microorganisms cling and grow in slime on the rocks as they feed on the organic matter.

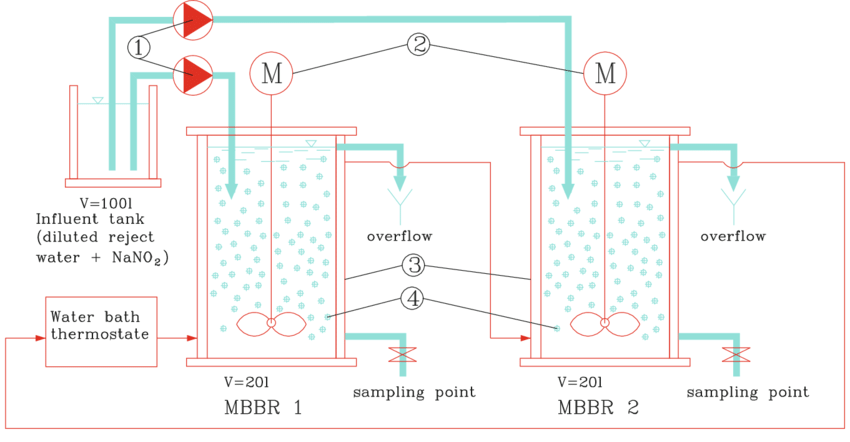

Moving Bed Bio Film Reactor (MBBR)

MBBR is an alternative offers an alternative of activated sludge system. MBBR systems are based on reactors that are filled with plastic carriers to provide a surface that is colonized by bacteria that grow into a biofilm. The reactors can be operated under aerobic conditions for BOD removal and nitrification or under anoxic conditions for denitrification. During operation, the carriers are kept in constant circulation. In an aerobic reactor, circulation is induced through the action of air bubbles injected into the tank by a coarse bubble diffuser system. In an anoxic reactor, a submerged mixer is typically supplied. The carriers can occupy up to 70% of the reactor volume on a bulk volume basis. Experience has shown that mixing efficiency decreases at higher percentage fills.